Basic steps |

Required tools |

Pushrod tube seals |

Pushrod tube seals. |

Degrease and wash engine. |

Degrease and wash engine |

Your basic SWB 1970 R50/5 |

The finned exhaust nut wrench. |

Remove exhaust. |

Exhaust nut removed. |

Correct assembly of exhaust hardware. |

Remove exhaust. |

Unbolt the headers from the mufflers. |

Remove exhaust. |

Remove carb. |

Remove carb. |

Carb removed. |

Remove the valve cover. |

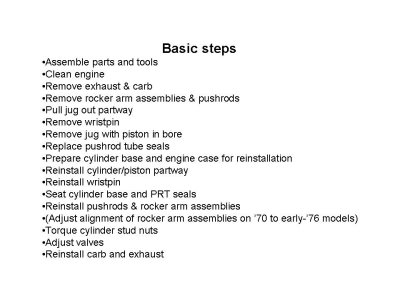

Removing rocker arm assemblies and pushrods. |

Remove rocker arm assemblies and pushrods. |

Remove rocker arm assemblies and pushrods. |

Remove rocker arm assemblies and pushrods |

Rocker arm assembly with needle bearings. |

Remove rocker arm assemblies and pushrods. |

Another way to do it is with screws on a board, and labeled. |

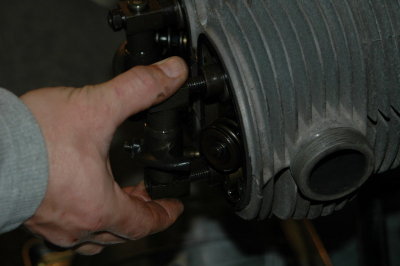

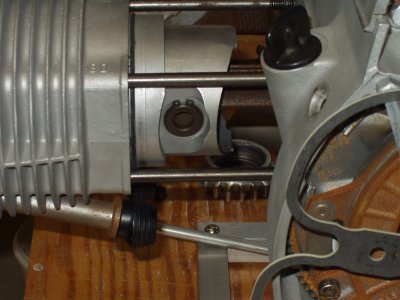

Pull jug out partway. |

Pull jug out partway. |

Pull jug out partway. |

Pull jug out partway. |

Pull jug out partway. |

Pull jug out partway. |

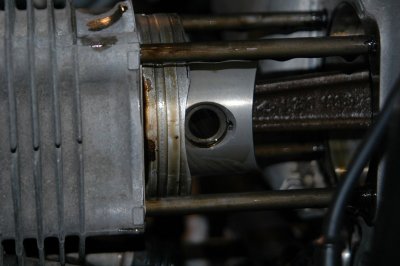

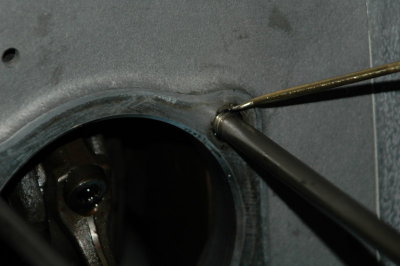

Remove wristpin. |

Remove wristpin. |

Remove wristpin. |

Remove wristpin. |

Remove wristpin. |

Remove wristpin. |

Remove wristpin. |

Remove wristpin. |

Inspect wristpin. |

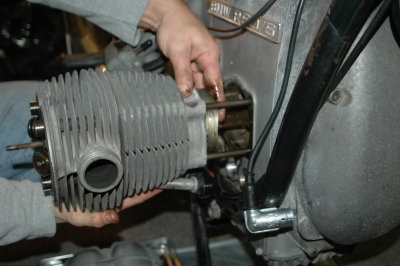

Remove jug with piston in cylinder. |

Remove jug with piston in cylinder. |

Finish removing the jug. |

Remove jug with piston in cylinder. |

Replace pushrod tube seals. |

Replace pushrod tube seals. |

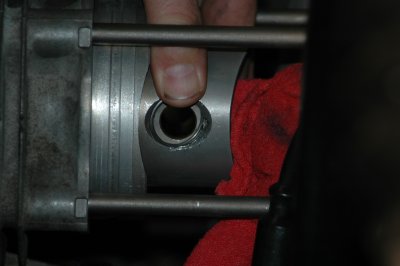

Detail view of piston crown. |

Replace pushrod tube seals. |

Correct piston orientation. |

Correct piston orientation. |

Replace pushrod tube seals. |

Prep cylinder base area for reassembly. |

Cleaning cylinder base. |

Cleaning cylinder base. |

Cylinder base gasket |

Cylinder base on jug suitably cleaned. |

Another view of the cleaned cylinder base. |

Small o-rings seal top cylinder studs. |

Close-up of large and small o-rings. |

Prepare cylinder base area for reassembly |

Cleaning the cylinder base area |

Cleaning the cylinder base area |

There, much better! |

Small o-ring on '76-and-later motors. |

Clean cylinder base area. |

Clean cylinder base area. |

Prepare cylinder base area for reassembly |

Hylomar |

Permatex High-Temp RTV Silicone |

Just a dab'll do ya |

Oil gallery outlet at the top cylinder stud. |

Correct thickness of sealant application. |

Applying sealant to cylinder base of jug. |

Prepare cylinder base area for reassembly |

New wire clip for wristpin. |

Installing the wire clip. |

Seat cylinder base and PRT seals |

Seat cylinder base and PRT seals |

Seat cylinder base and PRT seals |

Seating the seals by installing the bottom cylinder stud nuts first. |

Reinstall pushrods & rocker arm assemblies. |

Reinstall pushrods & rocker arm assemblies. |

Adjust alignment of rocker arm assemblies |

Aligning the rocker arm assemblies |

Correct alignment of the pushrod in the PRT |

Torquing the cylinder studs. |

Setting the valve lash. |

Setting the valve lash. |

Setting the valve lash. |

Refitting the valve cover. |

Reinstall exhaust and carb. |

Reinstall exhaust and carb. |

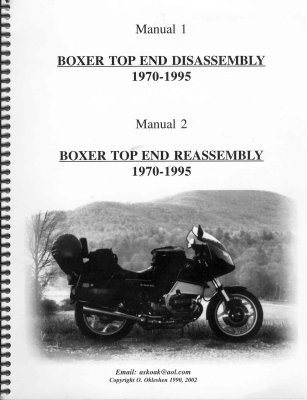

Oak's top end manual -- invaluable! |