Oostmolen in Gistel |

Oostmolen in Gistel 2 |

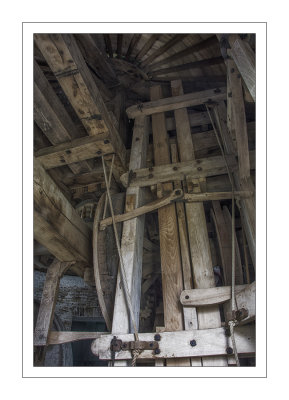

Oostmolen 3 -The name Post mill |

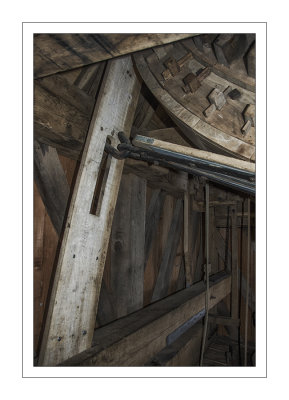

Oostmolen 4 - Wooden shaft with inserted steel sailhead |

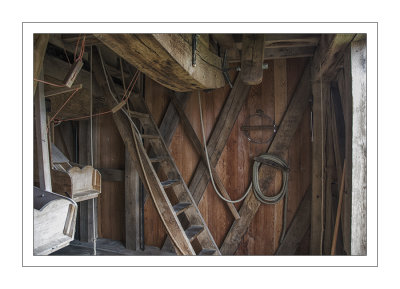

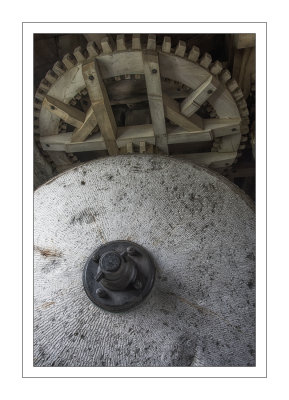

Oostmolen 5 - Wooden gear mounted on the shaft of the sails. |

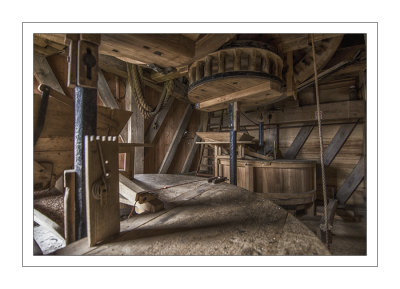

Oosqtmolen 6 - The brake |

Oostmolen 7 - The wooden gear |

Oostmolen 8 - Disconnecting the gear |

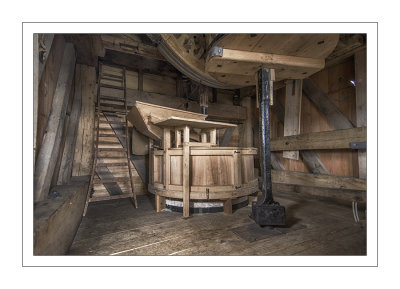

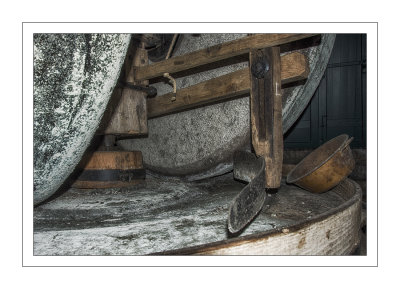

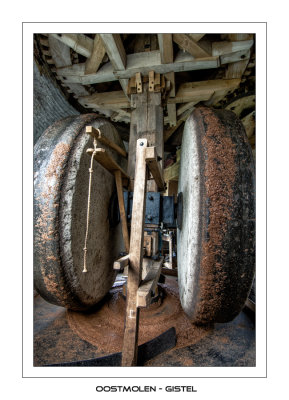

Oostmolen 9 - The millstones |

Oostmolen 10 - Tuning of the millstones |

Oostmolen 11 - tuning the stones 2 |

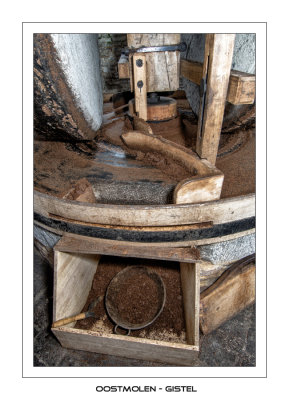

millstones and shaft to the oil mill. |

Oostmolen 12 - Flour collection and brake rope |

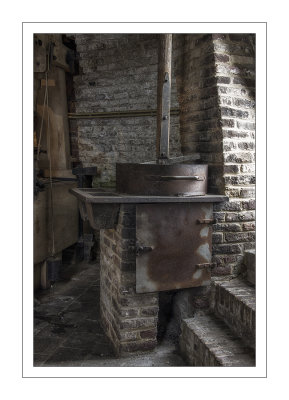

Oostmolen 13 - the oil mill |

Oostmolen 13 - The transmission |

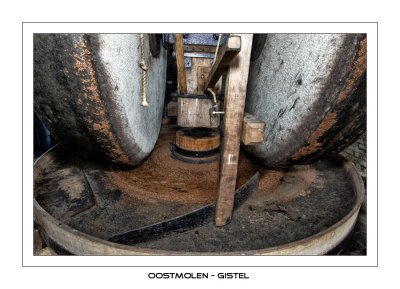

Oostmolen 14- scrapers |

Oostmolen 15-upright millstone and drive |

Oostmolen 16- Pan grinder drive |

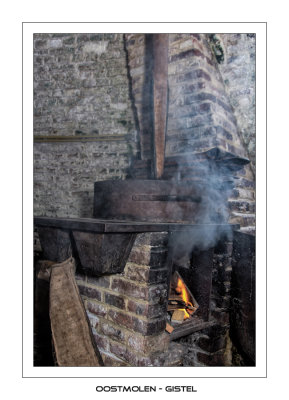

Oostmolen17- The fire |

Oostmolen 18- Drive for the stirrer |

Oostmolen 19- Fire and oil stamping bank |

Oostmolen 20- camshaft |

Oostmolen 21-stampers and camshaft. |

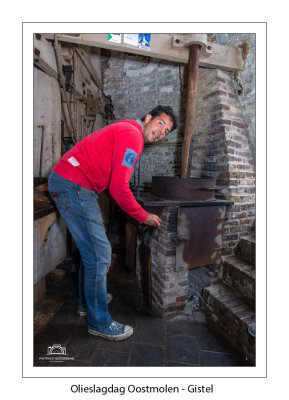

Making the fire under the warming plate |

Heating up |

The miller empties a sack of lineseed in the base of the panmill |

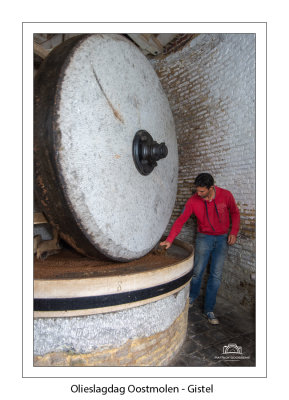

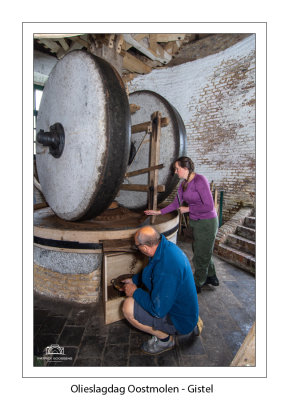

The crushing installation |

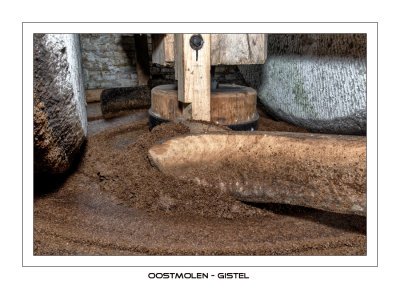

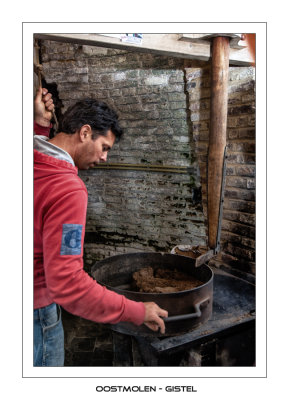

Crushing product |

The ejector |

The scraper |

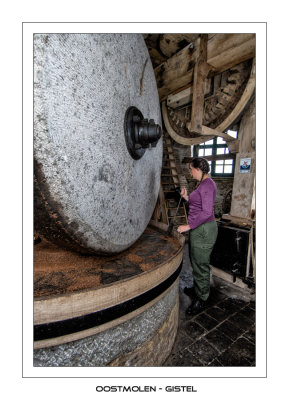

Controlling the process. |

Helping with a bruch |

Helping |

The ejector is pushed down by hand for better scraping |

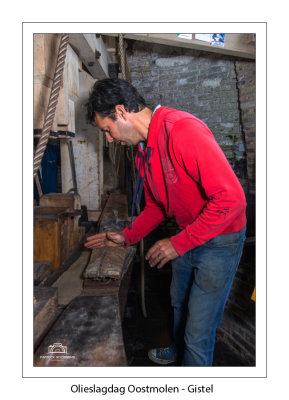

The miller overseeing the process. |

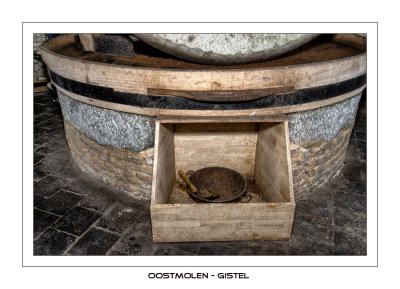

Close up of the recipient for the crushed product |

Collecting the crushed product |

The opening in the base |

Miller Benoit preparing the sacks |

The stirrer |

Miller Rebecca putting the crushed lineseed on the warning plate |

Pression pillows |

filling the pressing sacks |

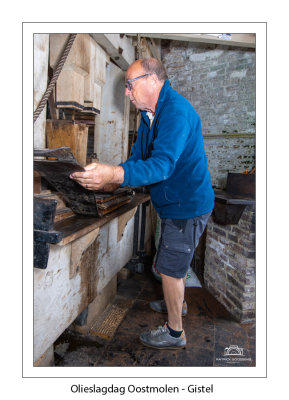

Flattening and spreading the product in the sacks. |

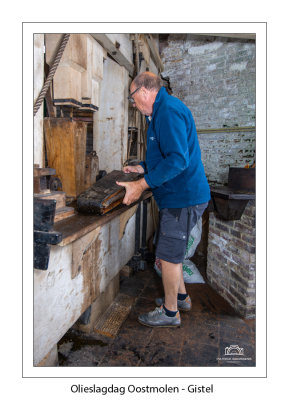

Miller Wilfried preparing the pressing pillow |

Closing the pillow |

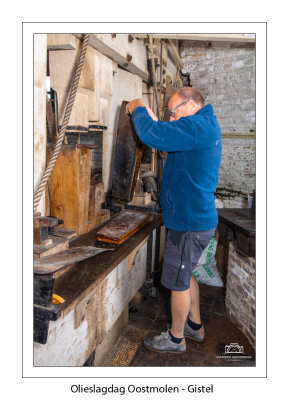

Putting the pillow in the pressing block |

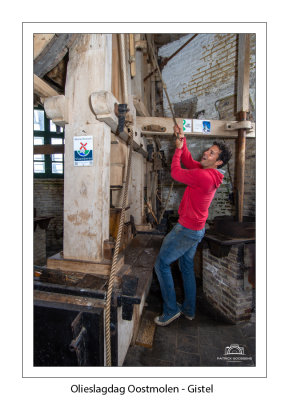

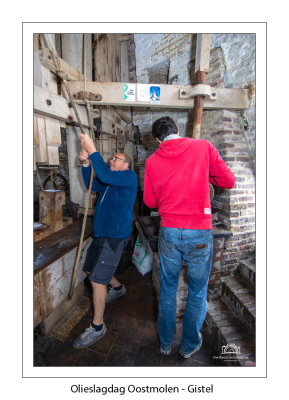

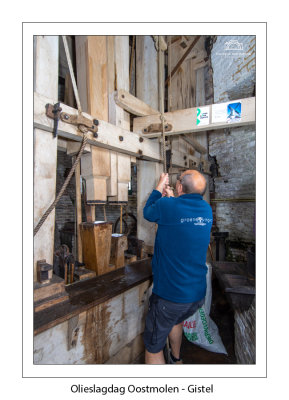

Pulling the rope to start the stamper |

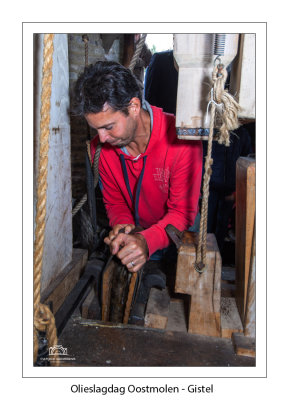

Miller Wilfried ends the stamper work by pulling the stamper back up |

Miller Benoit removing the presspillow with pressed product |

Hard work |