|

|

|

|

|

|

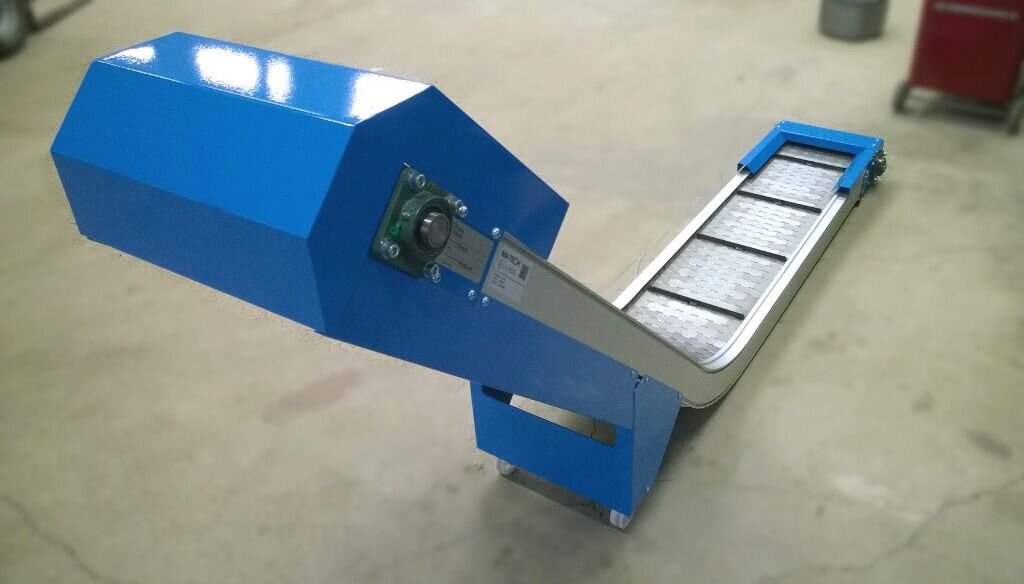

Magnetic chip conveyors are an essential tool for industries that deal with metalworking and machining processes, which often produce large amounts of metal chips, shavings, and other waste materials. In industries like automotive manufacturing, aerospace, and machining, the efficient handling and removal of these metal chips are crucial for maintaining smooth operations. These sharp, tiny, and sometimes tangled parts can be difficult to handle with traditional conveyor systems. These challenges are solved by magnetic chip conveyors, which use powerful magnets that attract ferrous metals and transport them safely. This creates a safer and cleaner working environment. These conveyors help eliminate the need for manual handling, minimize material loss, and improve overall efficiency by automating the chip removal process, making them indispensable in many industrial operations.

Magnets can be embedded in or under the belt of magnetic chip conveyors. These magnets create a magnetic field that attracts and secures ferrous materials, such as metal chips, as they travel along the conveyor system. It ensures metal shavings are kept in place while they travel from the machine to a collection point. By using magnetic force, the metal shavings are prevented from falling of the conveyor. This reduces material losses and maintains the production flow. The friction used in traditional conveyors can cause slippage or misalignment of the material. Magnetic conveyors eliminate these risks by providing a more secure and stable means of transporting metal debris, making them especially useful in environments where metal chips are generated continuously.

Magnetic chip conveyors are known for their versatility and adaptability to various applications. These conveyors can be customized to meet the specific needs of different industries, allowing for efficient handling of a wide range of metal chips, regardless of size or weight. The magnetic force of the conveyor is adjustable to match the size and weight of the metal chip. It can be designed with flat, inclined or curved belts to move materials horizontally as well as vertically. Magnetic chip conveyors are flexible enough to be used in a wide range of environments. Magnetic chip conveyors are designed to meet the specific needs of an operation. They can move material over short distances, or lift it to higher levels.

Beyond their adaptability, magnetic chip conveyors are highly efficient and help improve operational productivity. In many industries, time is of the essence, and any interruption to production can result in costly delays. Traditional conveyors, which rely on friction to move materials, are prone to jams, material slippage, and mechanical failures, which can lead to downtime. Magnetic chip conveyors, however, provide a continuous, smooth operation because the magnetic field secures the chips in place, reducing the chances of these issues occurring. As a result, magnetic conveyors help maintain a steady flow of materials, ensuring that production lines run without interruption. The magnetic force also holds metal chips, which reduces the need for human intervention and improves operational efficiency. This uninterrupted, efficient movement of materials leads to higher throughput and helps businesses meet their production targets with fewer disruptions. To obtain supplementary details please hop over to this website

Another significant advantage of magnetic chip conveyors is their ability to improve the safety and cleanliness of the workplace. The metal chips can be sharp, and if left on the ground or near equipment they could pose a danger to workers. In some industries, the presence of metal chips can also create a fire hazard, especially if they are mixed with oils or lubricants. These risks can be mitigated by magnetic chip conveyors, which collect and move the chips from working areas. This not only ensures a safer work environment but also prevents equipment from becoming clogged with debris. Magnetic chip conveyors reduce the risks of injuries and accidents by keeping the area they work in clean.

Magnetic chip conveyors also contribute to sustainable efforts, as they encourage the reuse and recycling of valuable materials. In industries that generate a high volume of metal chips, recycling these materials is often a priority. Magnetic conveyors can efficiently separate ferrous metals from other waste products, allowing businesses to recover and recycle the metal chips, which can be reused in manufacturing or sold to recycling companies. This helps reduce material waste and lowers the environmental impact of industrial operations. Magnetic conveyors improve metalworking efficiency by streamlining the process of metal recovery.