|

|

|

|

|

|

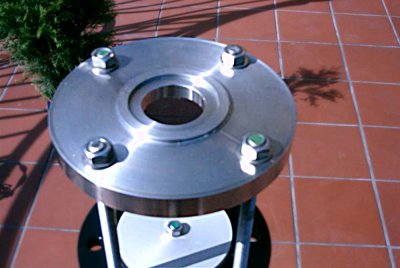

| Pawel Lancucki | profile | all galleries >> Pawel Lancucki - Amateur Astronomy >> ATM corner >> ATM projects related to Takahashi equipment >> Permanent pier for EM-100 mount | tree view | thumbnails | slideshow |

ss_pict0029.jpg |

ss_pict0015.jpg |

ss_pict0016.jpg |

ss_pict0017.jpg |

ss_pict0018.jpg |

ss_pict0021.jpg |

ss_pict0022.jpg |

ss_pict0023.jpg |

| comment | share |