Copper stills at Highland Park distillery |

Entrance at Highland Park Distillery (Orkney) |

Highland Park visitors centre |

Germination of barley (malting) at Highland Park distillery |

Drying of malt at Highland Park |

Warming up the kiln with burning coal and peat - Highland park |

Burning coal and peat |

Mash tun at Highland Park |

Warehouse at Highland Park |

Warehouses at Highland Park |

Brora old distillery |

Brora old distillery |

Brora warehouses |

Clynelish farm - Brora |

Clynelish - transportation of draff (for cattle feed) |

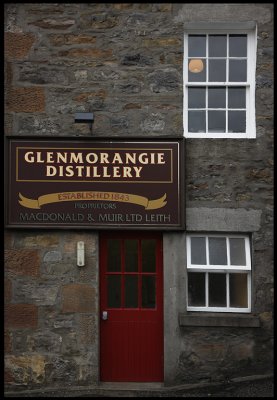

Glenmorangie distillery - near Tain |

Glenmorangie Distillery |

Glenmorangie Visitors centre |

Delivery of malt (malted barley) to Glenmorangie distillery |

Mashing tuns at Glenmorangie |

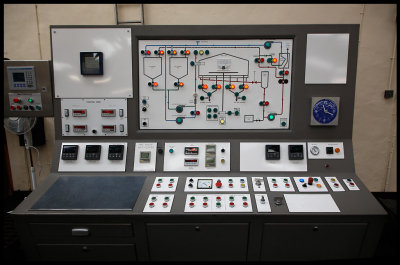

Mashing monitoring at Glenmorangie distillery |

Wort passed into wash backs |

Fermentation at Glenmorangie |

Active fermentation tun at Glenmorangie distillery |

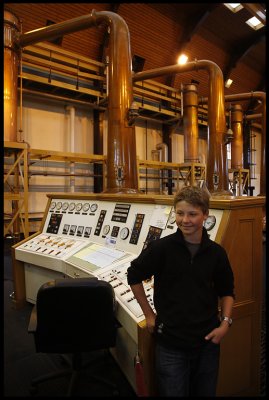

Controling the process at Glenmorangie |

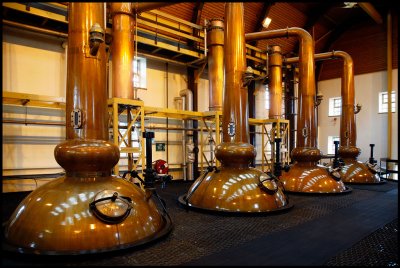

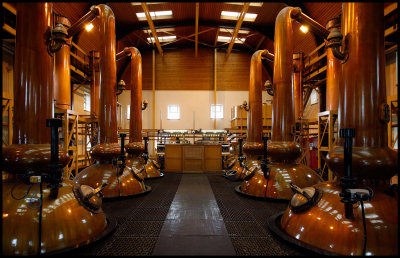

Glenmorangie copper pot stills - highest in the world.... |

The impressing copper pot stills at Glenmorangie |

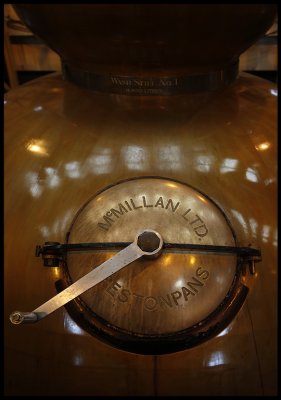

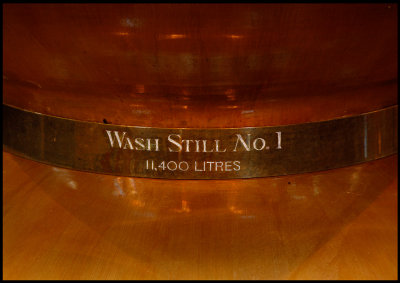

Glenmorangie, wash-still |

Glenmorangie, wash-still |

Still heater at Glenmorangie |

Hydrometer helping to "remove only the heart of the run" |

Inside the hydrometer spirit is floating all the time |

Monitoring the distillation process at Glenmorangie |

Martin taking part of the distillation..... |

Glenmorangie warehouse with lots of barrels |

Glenmorangie warehouse with lots of barrels |

Casks transported for maturation in the warehouse - Glenmorangie |

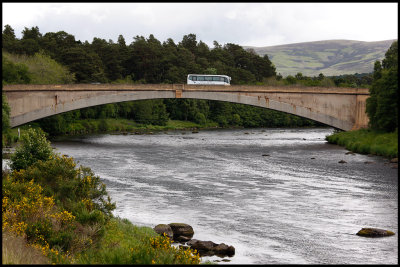

The famous River Spey |

Cragganmore - old and reliable |

Glenfarclas warehouse - where maturation takes place |

An empty mash tun at Glenfarclas |

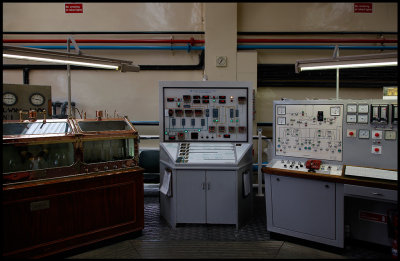

Control of the distillation process at Glenfarclas |

Control of the distillation process at Glenfarclas |

Glenfarclas stills |

The neck og the still where spirit condensates |

Control of the distillation process (hydrometer) at |

Copper still at Glenfarclas distillery |

Copper still at Glenfarclas distillery |

Control of the distillation process (hydrometer) at Glenfarclas |

Monitoring temperature inside the copper stills at Glenfarclas |

Glenfarclas warehouses |

Loading barrels at Glenfarclas |

Newly filled barrels at Glenfarclas distillery |

Loading barrels at Glenfarclas |

Glenfarclas firebrigade..... |

Worker at Speyside Cooperage |

Fixing old barrels at Speyside Cooperage |

Worker at Speyside Cooperage |

Pressing down the barrelrings at Speyside Cooperage |

Speyside Cooperage also manufacturers of new barrels |

Testingarea at Speyside Cooperage |

Dufftown surroundings |

Dufftown - Whisky Capital |

Old Parkmore distillery in Dufftown |

Parkmore warehouses |

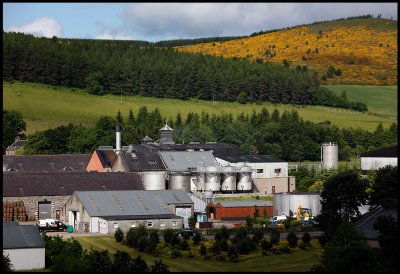

Glenfiddich distillery seen from Parkmore area |

Glenfiddich stills - small but many..... |

Martin in Glenfiddich shop |

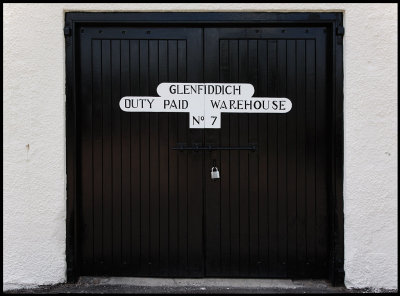

Glenfiddich Warehousedoor |

Mortlach distillery with only one employee |