|

|

|

|

|

|

| Topics >> by >> what_does_three_mesh_types_f |

| what_does_three_mesh_types_f Photos Topic maintained by (see all topics) |

||

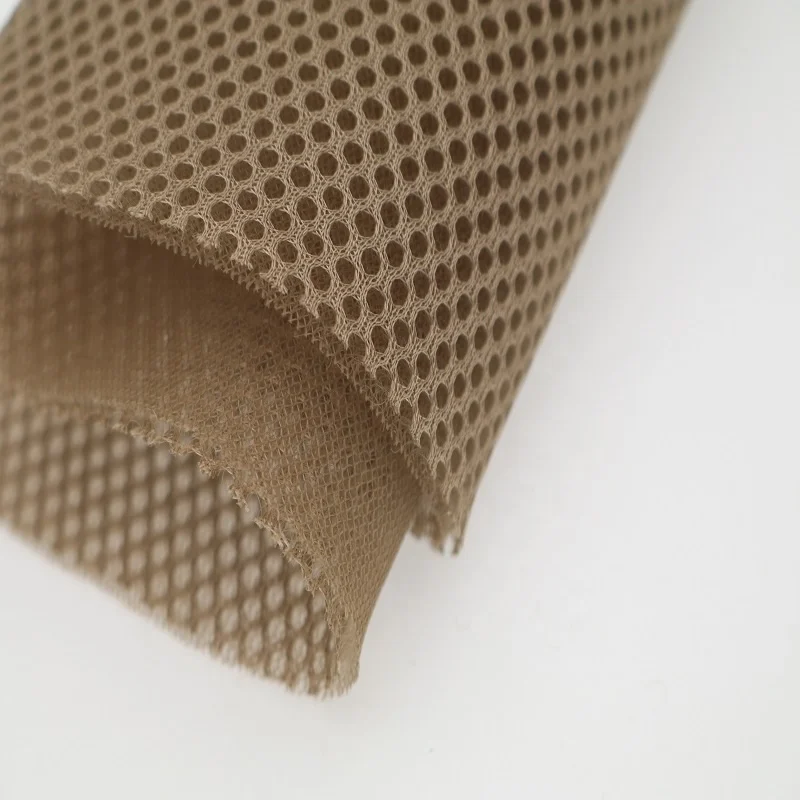

The Best Strategy To Use For 3d Spacer Fabric, Polyester, 3d Spacer Air Mesh FabricKnit mesh material is most typically made from either polyester or nylon yarns. While the two synthetic polymers share some propertiese. g., lightweight, durability, and tear resistancethere are several crucial distinctions that make them appropriate for various applications. has a smoother and softer feel than, which in some circumstances makes it more ideal for usage in applications needing high aesthetic quality or user comfort. is hydrophilic (soaks up water), while is hydrophobic (repels water). As such, the former is most likely to be slowed down with water in high-moisture or high-humidity environments, while the latter dries quickly in marine and marine settings. are innately resistant to wear from bending and stretching, while are inherently resistant to heat and UV rays.  And again, it requires to be kept in mind that these intrinsic qualities are basic at finest. Finishing and treatment are essential to performance. See listed below. Additional Info of Material Finishing and Treatment The practical and aesthetic properties shown by a polyester mesh fabric are reliant upon lots of factors. For the purposes of this short article, we will focus on the final phases of textile production, otherwise referred to as "the finish". Top Guidelines Of Mattress - WikipediaWhen finished, these processes can affect the texture, weight, firmness, colorfastness, and resistances (UV, fire, and so on) of the last product. As indicated above, the homes displayed by a totally completed and dealt with polyester mesh fabric vary depending upon the requirements of the application and the industry. Some consist of: Topically applied anti-microbial finishes eliminate bacterial development on the surface of the fabric  This makes the need for these types of surfaces vital for equipment utilized in the medical and health care markets. They are also suitable for sporting devices as they reduce the spread of odor-causing bacteria. In operations involving sensitive electrical and electronic elements, it is necessary to minimize the accumulation of fixed charge. Neglected material exposed to UV rays fades and degrades gradually. As such, polyester mesh intended for usage in outdoor environments (e. g., recreational devices) needs the addition of UV inhibitors to the fabric finish or dye formulation to retain the initial stability. One of the most frequently used surfaces; utilized to achieve FR compliance in the automobile market, aeronautical market, and architectural interior industry (believe drapes and indoor rec areas). |

||

|

||