|

|

|

|

|

|

| Topics >> by >> not_known_details_about_xome |

| not_known_details_about_xome Photos Topic maintained by (see all topics) |

||

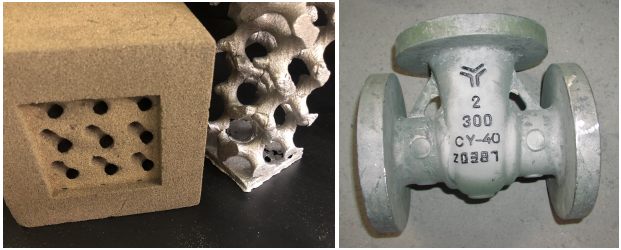

All About The New Pattern for Prototyping - Modern Machine Shop Required it tomorrow? The Latest Info Found Here 's next-day 3D services include Poly, Jet, FDM and SLA. All of these technologies, FDM, Poly, Jet and SLAare perfect for tasks that require high resolution and excellent surface finish with the durability of engineering-grade thermoplastics. At Fathom, we comprehend the value of deadlines and are ready to assist you cross that job off your list. A large prototype allows you to discover any style problems early in the item development procedure prior to investing time and cash in massive production. Present your large prototype to clients to find out if your item is easy to use in order to collect valuable client fulfillment information. Large prototypes may also be used as a visual model for investors, assisting you acquire capital for production. Getting My Editor's Pick: Stacking up Sand for the Digital Industrial Foundry To WorkFind out more about large models. 3D Printing vs. Injection Molding 3D printing manufacturing and injection molding are substantially different production processes. 3D printing is an additive production method in which parts are built layer-by-layer up until an item is created. 3D printing is a great suitable for projects that need a lower volume of items, complex and detailed designs and any job that might need fast changes early in the item development cycle.   Once the material has actually cooled, the part is eliminated from the mold. Injection molding is best for big volumes, parts that are not complicated or fragile and parts that require enhanced strength. Find out more about 3D Printing vs. Injection Molding 3D Printing Quotes Usage Fathom's online Smart, Quote platform to get your immediate 3D printing quote. Examine This Report about Sand Casting Applications Using Rapid Prototyping TechnologyWhy? We can take on tasks of various levels of complexity, technology option, or job size. Getting a quote is a basic, three step procedure. Initially, choose your preferred technologyadditive or standard. Second, upload your file to the instant online quote tool, then select your preferred products, finishes and amount. Lastly, submit your quote for pricing and shipping choices. |

||

|

||