|

|

|

|

|

|

| Topics >> by >> some_of_prototyping_short |

| some_of_prototyping_short Photos Topic maintained by (see all topics) |

||

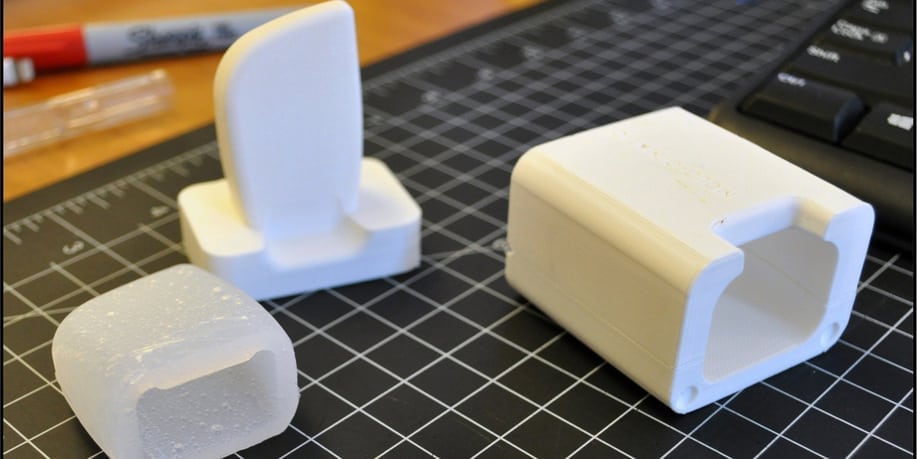

The Single Strategy To Use For Rapid Prototype Mold Making: 5 Ways to Make Your ProcessIf your concept is easy enough to construct and use, a functional model might be the best choice. Remember, Read More Here can always grow the model throughout the procedure. Use a throwaway prototype to gather info, develop a display screen model to figure out the visual appeals and continuously develop an evolutionary prototype till you have actually accomplished your vision. Use as couple of parts as possible in the construction, and keep the aesthetic appeals of the style reasonable. Keep in mind, you are creating the product to serve a particular function the model's task is to figure out whether that is possible. Remaining focused on the goal will keep the core of your principle undamaged.   Operationally or aesthetically, you may need to review the model and make adjustments. Improvement, in both kind and function, is necessary if you wish to accomplish a nice prototype. While you may have been able to information the complete principle and even start to put a prototype into advancement, you ought to not be averse to looking for out professional support. The Basic Principles Of How Do I Create Physical Prototype? : r/Inventions - RedditBy depending on the understanding and know-how of an skilled prototype maker, you will guarantee the model is nice, functional and mirrors the quality of the idea. Producing a feasible prototype can be a difficult procedure. Whether you have actually already developed an initial variation of a prototype, or if you've got a strong concept you wish to bring to life, a professional manufacturing service concentrating on model production will assist you complete your vision.  SIMTEC PROTOTYPE production For nearly twenty years, SIMTEC has provided total turnkey services to leading worldwide organizations that need customized, top quality liquid silicone rubber and LSR 2-Shot parts. From consumer and vehicle parts to medical devices, we've provided a range of markets with highly flexible injection-molded LSR parts. No matter the application, liquid silicone rubber parts can carry out efficiently. SIMTEC is proud to offer prototyping services to our customers who are seeking reputable parts and parts for their latest developments. Throughout the style and prototyping procedure, we work carefully with our clients to ensure we manufacture each part according to their specific style. |

||

|

||