|

|

|

|

|

|

| Topics >> by >> the_single_strategy_to_use_f |

| the_single_strategy_to_use_f Photos Topic maintained by (see all topics) |

||

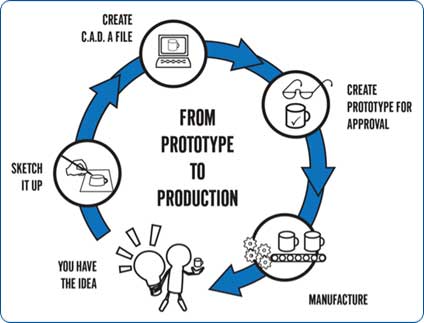

The 9-Minute Rule for Prototype Factory: additive manufacturing withoutIf death and taxes are 2 warranties in life, money and time are the 2 constants when taking an idea from the model phase through new product introduction (NPI) into business launch. However have you ever questioned what it appears like to take an item from model to production? The Latest Info Found Here 's a complex procedure that combines creativity and procedures. The timeline for development is as private as the person who developed the product. Nevertheless, there are a number of turning points to try to find along the method. If you're dealing with a producer who can assist you with design for manufacturability (DFM), so much the much better. Such producers have internal engineering (or trusted engineering sources) and sales teams with experience in identifying whether your principle will translate into a scalable production chance.  Sourcing + RFQ You supply a drawing bundle, and sometimes a prototype to your producer. Their goal is to offer you with a comprehensive quote and task proposition to move into mass production. At this moment, your manufacturer carefully evaluates the style to determine ability, prices and tooling requirements. The sourcing team examines raw product and component schedule. What Does The 5 Phases for Completing Prototype Development Do?The outcome is a quote and job method that are most efficient and effective for you. 2. Tooling, Testing and Non-Production Release Once you've approved the quote and project approach, your item enters the tooling/sampling stage, which is also understood as non-production release (NPR). During this stage tooling is completed and the design is become a physical sample that can be consistently duplicated while satisfying item requirements.  Meanwhile, an initial quality treatment (QP) is described versus the item specifications. The QP is a living file continuously updated and covers all form, fit and practical requirements you have, including in-process documents, third-party certifications or raw product requirements. This process is really iterative. Preliminary samples frequently require tweaking. There may be extra design changes, indicating extra samples and additional time.   Engineers will change till they get it right. This is excellent. You do not wish to need to make modifications later while doing so. 3. Production Introduce After a pilot production run a short-term run of a little batch, typically 200 to 500 pieces, depending upon complexity, size and volume of the product your sample has been certified and your item is prepared for mass production. |

||

|

||