|

|

|

|

|

|

| Topics >> by >> tension_control_bolts_suppli |

| tension_control_bolts_suppli Photos Topic maintained by (see all topics) |

||

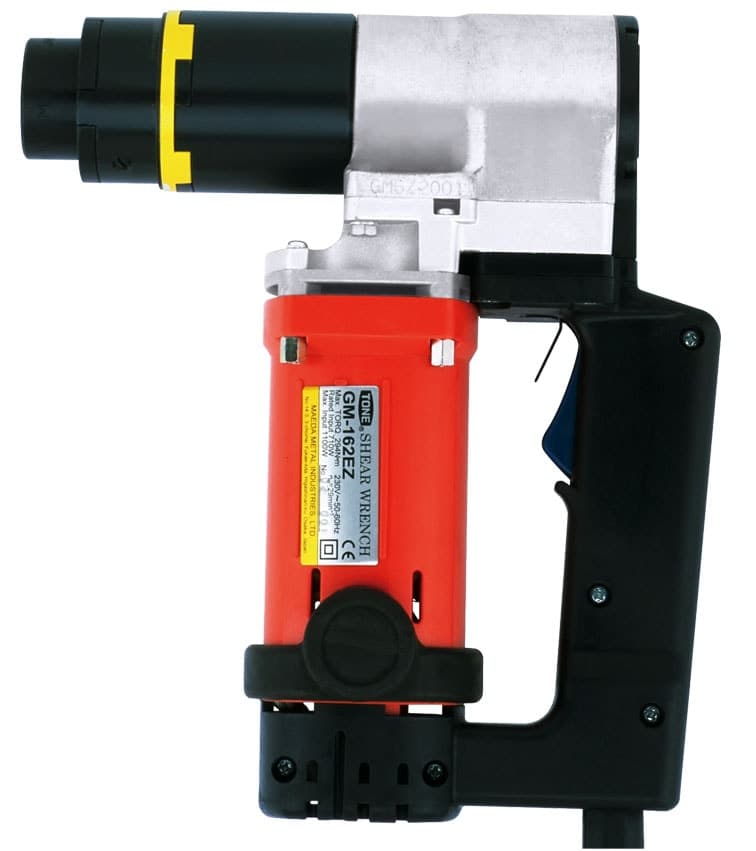

6.6 Methods for Fully Tensioned Installation - American Can Be Fun For AnyoneA tension control bolt (TC bolt) is a strong bolt used in steel frame building. The head is usually domed and is not developed to be driven. The end of the shank has a spline on it which is engaged by a special power wrench which prevents the bolt from turning while the nut is tightened. A tension control bolt is a pre-assembled bolt, nut, and washer used particularly in steel frame building. Likewise referred to as a TC bolt, they possess a domed head rather than a hex head because they are installed from a spline on their other end. This spline connects with a special power wrench for setup.  Stress control bolts come perfectly pre-lubricated by the maker. They are ready to be set up with a shear wrench. This wrench has an inner and an external socket. The inner socket rotates the spline clockwise and the external socket turns the nut counterclockwise. Once Answers Shown Here has actually been attained, the spline breaks off. ASTM F1852 - 14 Standard Specification for “Twist Off” Type Can Be Fun For EveryoneThere is just one lot number associated with the stress control bolt assembly and they come specifically lubed. They are controlled by the AISC, American Institute of Steel Building, and RCSC, Research Council on Structural Connections. The single most unique function of the stress control bolt is that it is set up with a specifically calibrated shear wrench that takes the guesswork out of achieving the right preload (tension developed in a fastener when it is tightened). Many feel that stress control bolts are more cost-effective due to the fact that they need only one individual for their setup and assessment. For that reason, installation goes much faster and with fewer errors. Tension control bolts must adhere to specifications noted by the RCSC, as mentioned prior to and any degradation of the lubricant on the bolt will cause it to stop working examination. Galvanized bolts have a more durable lube on them as compared to the water soluble lube on the plain bolts, but you still must save them correctly too. If something takes place to your stress control bolts out in the field, you can not just re-lubricate them yourself. They must be sent back to the manufacturer for them to make the corrective steps and retest them. |

||

|

||