|

|

|

|

|

|

| Topics >> by >> 50_cool_things_to_3d_print_f |

| 50_cool_things_to_3d_print_f Photos Topic maintained by (see all topics) |

||

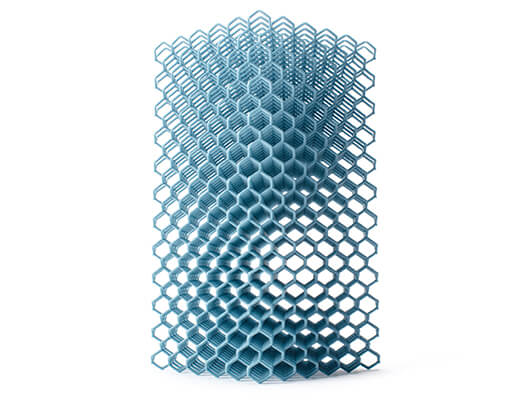

The Basic Principles Of Print3D - 2019 - SOLIDWORKS HelpBeginning from either geography optimization results or an imported CAD geometry, support structures can be easily produced and enhanced. Style alternatives can be quickly checked out and examined without leaving the familiar Inspire user environment. The innovative thermo-mechanical simulation allows design engineers to establish parts all set for additive production. By recording 3d print of the printer type, with Inspire Print3D designers can evaluate and quickly customize critical procedure variables. Inspire Print3D streamlines the identification and correction of potential contortion, delamination and extreme heating issues before developing a part. Additional production procedure analyses can be carried out leveraging third-party tools readily available through the Altair Partner Alliance, all on one license.   You can use Print3D to print 3D models of your models when you have a 3D printer set up in your area. SOLIDWORKS supports 3D printing of models which contain surface area bodies and graphics bodies just if they form a water tight manifold volume. You can 3D print surfaces or graphics bodies, offered they form a watertight manifold volume. If your 3D printer producer uses the SOLIDWORKS 3D Print API, the 3D printing fast prototyping dialog box opens to assist you in printing. Microsoft's Windows 3D printing flow utilizes an XML-based information format called 3D Production Format (3MF). Software application applications that support this format convert their data to 3MF format and send it to the operating system's print spooler for 3D printing. The 2-Minute Rule for Upload 3D Model - 3D Printing Service - i.MaterializeIn the Residential or commercial property, Supervisor, you can define alternatives on the Settings and Sneak peek tabs: Select a printer from a list of available printers. Orient and scale your model within the print volume specified by the selected printer. Select print options for quality, infill portion (density), supports, and raft. Save the file to a format used for 3D printing. Determine faces that require support. Show striation lines to determine whether the print resolution is adequately great. We are empowering individuals to produce without limitations for a cost-effective, personalized, and sustainable world. Discover how Stratasys developments help the world's leading organizations change lives, gain service dexterity, and seize competitive advantage with 3D printing. |

||

|

||