|

|

|

|

|

|

| Taylor Cobb | profile | guestbook | all galleries | recent | tree view | thumbnails |

Reliable scaffolding erection and taking apart require rigorous training, comprehensive inspections, and adherence to regulatory criteria. Appropriate training programs infuse vital abilities for safe operations. Assessment checklists ensure component honesty and security. Utilize time-saving setting up methods while prioritizing safety and security. Key considerations for dismantling include risk analyses and adhering to maker standards. Keep upgraded on guidelines and give detailed training for compliance. Best safety and security and effectiveness are achieved with a commitment to best techniques.

Proper training is essential for ensuring the risk-free and efficient erection and taking apart of scaffolding structures. Workers associated with these tasks must undertake extensive training programs to create the needed abilities and knowledge needed to take care of scaffolding equipment properly. Training ought to cover a range of topics, including appropriate assembly and disassembly strategies, load capacities, drop defense measures, and danger acknowledgment.

Efficient training programs not only focus on skill growth but also emphasize the importance of appropriate guidance during scaffolding procedures. Supervisors play a critical function in managing the erection and dismantling processes, guaranteeing that all safety protocols are adhered to, and intervening in situation of any type of deviations from the well established procedures. By offering adequate training and guidance, business can alleviate the risks connected with scaffolding job and create a safer atmosphere for their employees.

Continual skill advancement via regular training sessions and updates is important to make certain that workers stay informed about the current safety requirements and ideal methods in scaffolding erection and taking down. By buying correct training and supervision, firms can advertise a culture of safety and avoid mishaps on building and construction sites.

A vital component of assuring security during scaffolding erection and taking apart is the application of a comprehensive evaluation checklist. Safety safety measures should be carefully complied with to minimize risks associated with operating at elevations.

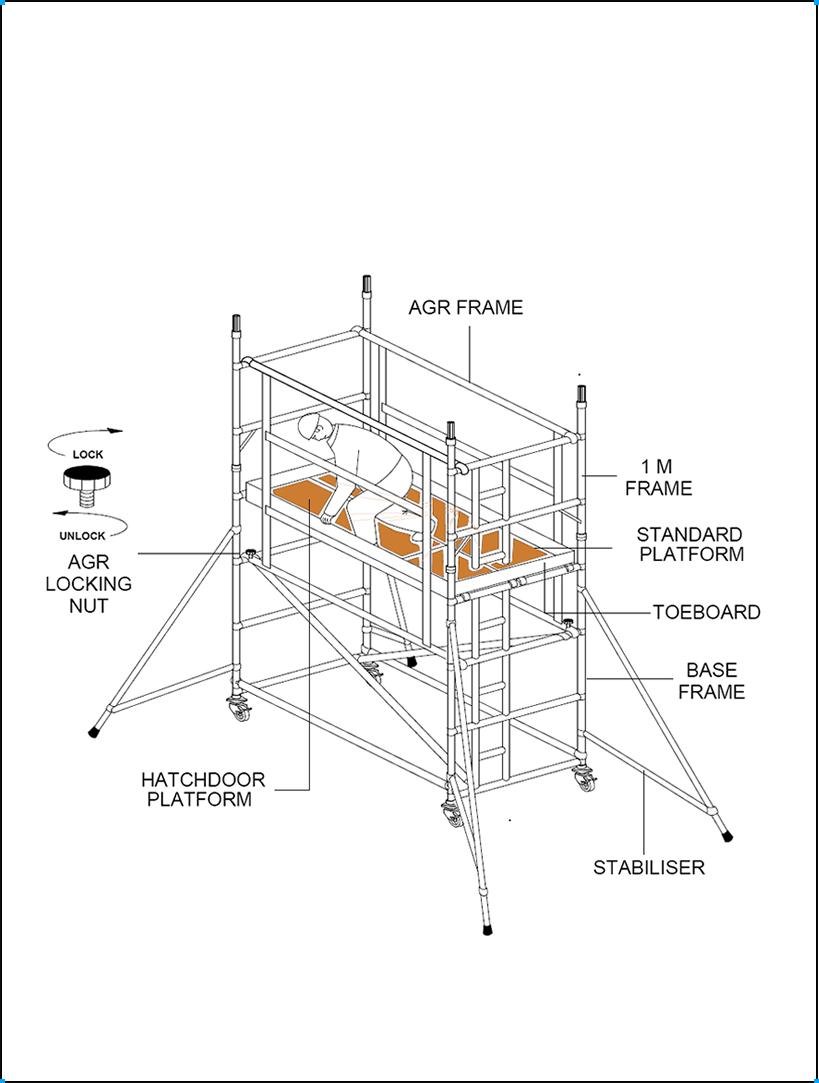

The inspection list for safety and security ought to include an in-depth examination of the scaffold elements, such as frameworks, dental braces, slabs, and guardrails, to confirm they remain in great problem and correctly set up. Regular devices upkeep is important to support security standards, consisting of looking for any type of indicators of damage, rust, or architectural damages.

Furthermore, verifying that all locking pins, screws, and links are safe and secure is critical to prevent mishaps. Examinations should also encompass an analysis of the scaffold foundation to confirm stability and weight-bearing capability.

Applying structured treatments is crucial for making best use of effectiveness in scaffolding setting up strategies. To accomplish this, consider the following:

Utilize Time-Saving Methods: Include reliable assembly processes such as pre-fabricated elements or modular systems. This can greatly reduce setting up time and labor prices, leading to general project financial savings.

Check Out Cost-Effective Solutions: Select cost-effective products and devices without jeopardizing security. This could entail renting specialized tools or using sturdy yet economical scaffolding materials to reduce costs.

Welcome Innovative Technologies and Lasting Practices: Integrate ingenious construction innovations like digital modeling or advanced scaffolding systems that advertise sustainability. These practices not only boost effectiveness yet additionally contribute to a greener atmosphere by minimizing waste and energy usage.

When taking down scaffolding frameworks, prioritizing safety measures and efficient disassembly strategies is essential for guaranteeing a smooth and secure procedure. Prior to launching the taking down process, a comprehensive risk evaluation need to be performed to determine prospective risks and carry out ideal control actions. https://lambethscaffolding.co.uk Preparation plays a significant role in ensuring that the dismantling process is carried out methodically and securely.

Techniques for taking down scaffolding vary depending on the sort of structure and the complexity of the assembly. Making use of the right tools is vital for a safe and effective taking down procedure. This may include devices such as scaffolding spanners, wrenches, and raises to assist in the disassembly of parts.

To lessen threats throughout taking down, it is very important to adhere to supplier standards and sector best practices. Correct training for employees associated with taking apart tasks is likewise essential to make sure that they excel being used the equipment and complying with security protocols. By prioritizing safety, using ideal techniques and devices, and performing comprehensive risk analyses and preparation, the taking down of scaffolding structures can be finished successfully and securely.

Focusing on adherence to governing requirements is critical when it comes to dismantling scaffolding frameworks to assure a safe and compliant workplace. Ensuring conformity with policies entails several key practices:

Governing Oversight: On a regular basis review and stay updated on the regulative standards set forth by appropriate authorities regarding scaffolding taking apart procedures. This includes understanding specific guidelines related to the taking down phase, such as appropriate series, devices needs, and precaution.

Training for Compliance: Supply extensive training to all personnel associated with the dismantling procedure. Training ought to cover regulatory demands, risk-free taking apart practices, recognition of prospective dangers, and emergency situation procedures. Normal correspondence course should be conducted to preserve continued adherence to compliance standards.

Paperwork and Coverage: Keep thorough records of all taking down activities, consisting of safety and security assessments, equipment checks, and personnel qualifications. Proper documentation makes sure transparency and accountability, promoting governing audits and showing a dedication to compliance with market regulations.

During scaffolding erection and taking down, common obstacles include time management, control problems, absence of correct training, and supervision. These challenges can result in safety and security dangers, hold-ups, and inadequacies otherwise dealt with properly.

Weather conditions can significantly impact the security and efficiency of scaffolding job. Severe wind, rainfall, or snow can present safety and security dangers and hinder progress. Safety and security safety measures, such as regular climate surveillance and proper security procedures, are essential.

To preserve the architectural honesty of scaffolding throughout a task, attentive assessment of links is important. Proper supporting also plays an essential role in guaranteeing security and safety. Regular checks and adherence to safety guidelines are essential.

Harness and platform security are vital in ensuring risk-free and effective scaffolding erection and dismantling. Correctly examining and using devices like wrenches, hammers, and levelers can enhance the process, advertising worker security and project performance.

Improving interaction and improving control amongst employee during scaffolding work is essential to avoid mishaps and delays. Clear instructions, routine instructions, making use of signaling approaches, and developing an effective chain of command can simplify operations and guarantee safety and security.

To summarize, adherence to appropriate training, extensive evaluation lists, effective setting up methods, essential factors to consider for taking down, and compliance with guidelines are necessary for safe scaffolding erection and dismantling techniques. https://lambethscaffolding.co.uk/index.html

By following these best practices, employees can minimize the danger of accidents and injuries on building sites.

It is vital that all people involved in scaffolding operations prioritize safety measures to ensure a protected work environment.