|

|

|

|

|

|

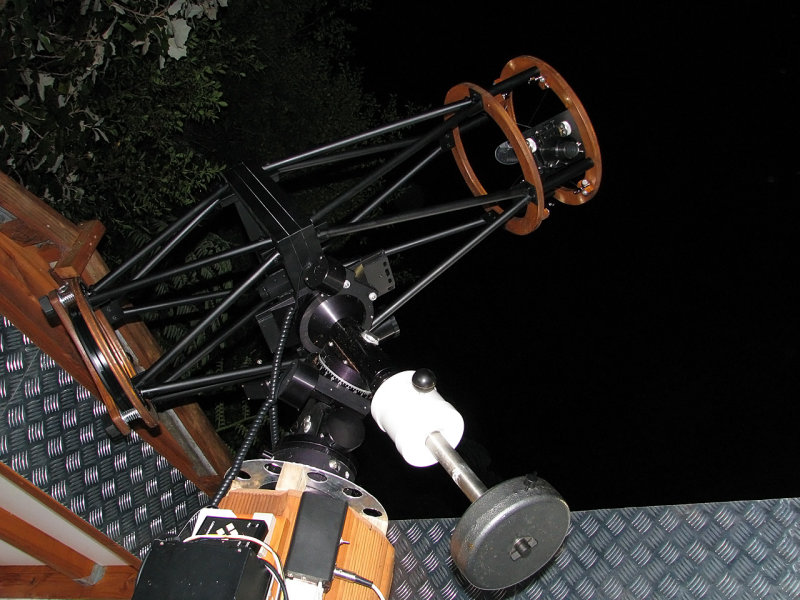

| Rolf Olsen | profile | all galleries >> Astrophotography >> 10 inch Serrurier truss Newtonian | tree view | thumbnails | slideshow |

| comment | share |

| Best Annabelle Dollhouse From Kidkraft for Little Ones | 25-Dec-2017 16:29 | |

| SmartmilToys.com | 12-Nov-2016 13:05 | |

| John Ailshire | 26-Mar-2014 06:16 | |

| mark | 26-Jun-2012 12:27 | |

| Michael, from Romania | 06-Apr-2012 09:23 | |

| Ramón from El Salvador | 24-Mar-2012 23:41 | |

| Guest | 18-Jan-2012 02:34 | |

| Ted Meyer | 27-Nov-2011 19:16 | |

| Rolf Olsen | 06-Nov-2011 09:58 | |

| Pavol | 01-Nov-2011 23:41 | |

| Lennart Waara | 22-May-2011 11:22 | |