|

|

|

|

|

|

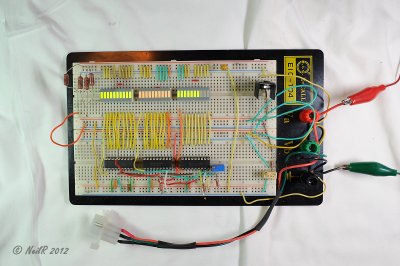

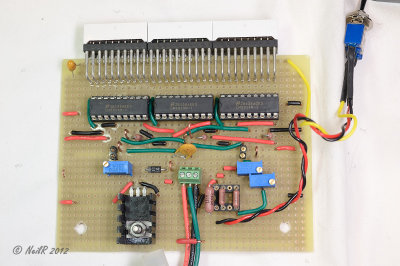

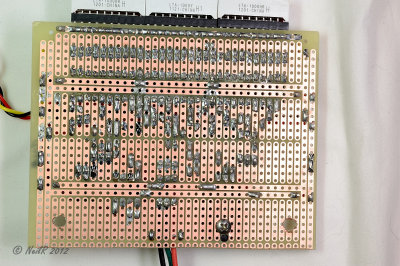

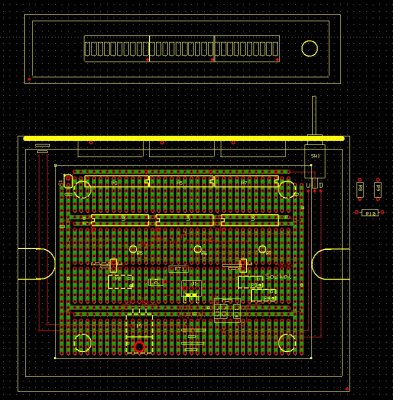

| Neil Rothschild | profile | all galleries >> 1985 RX-7 GSL-SE >> Air/Fuel Meter | tree view | thumbnails | slideshow |

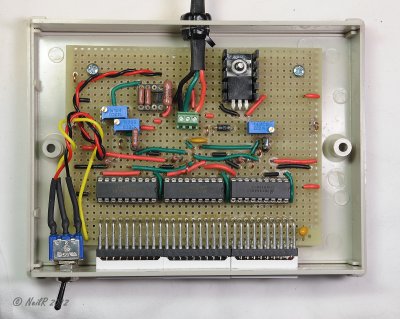

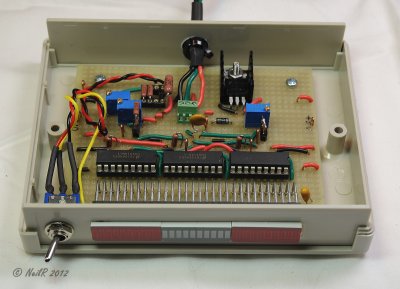

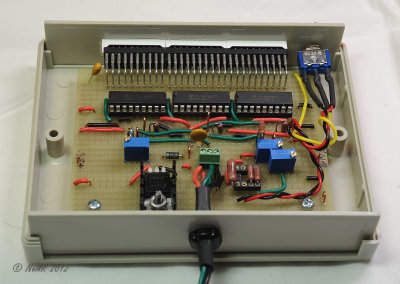

DSCN_260686.JPG |

DSCN_260691.JPG |

DSCN_260698.JPG |

DSCN_260703.JPG |

Board Layout |

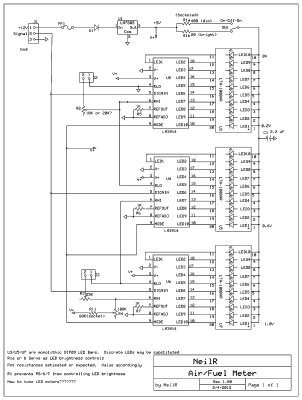

Schematic |

DSCN_260705.JPG |

DSCN_260707.JPG |

DSCN_260717.JPG |

DSCN_260720.JPG |

DSCN_260721.JPG |

DSCN_260722.JPG |

DSCN_260724.JPG |

| comment | share |