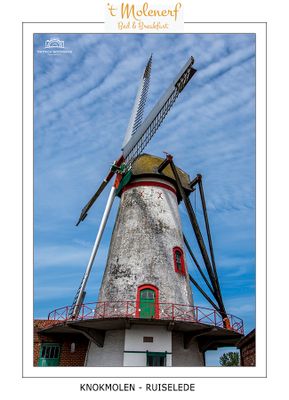

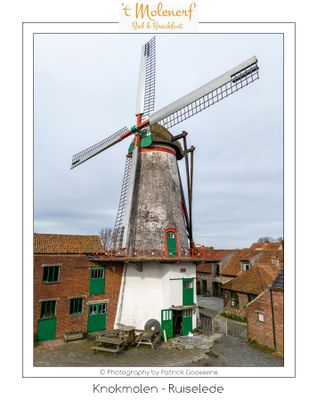

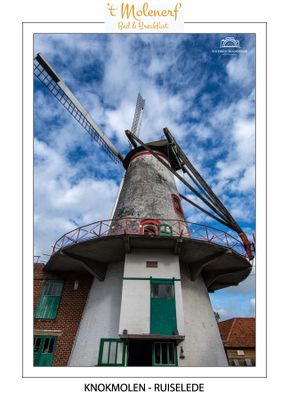

De knokmolen from 1840, a must see windmill in Belgium |

Susy and daughter Yana |

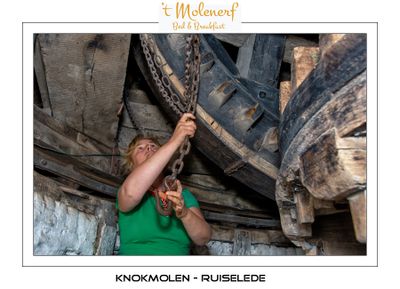

Susy the miller |

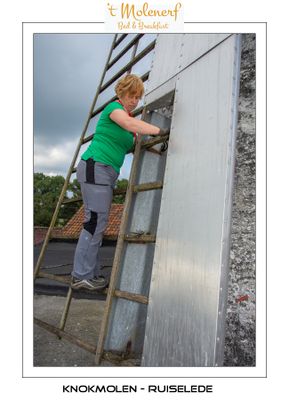

Yana turning the windmill in the wind direction |

Susy turning the mill in the right wind direction. |

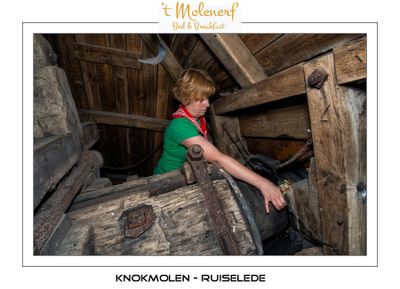

Unlocking the air brakes |

Working together unlocking the air brake |

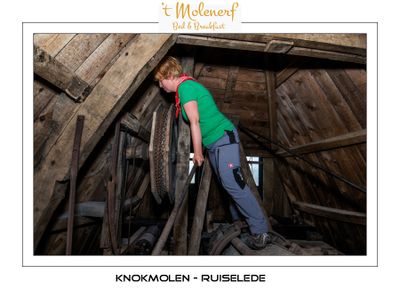

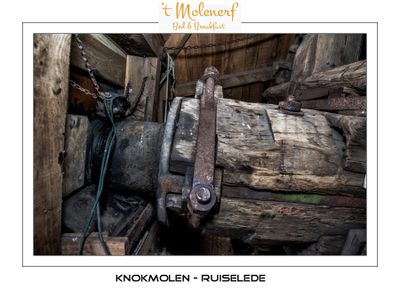

Windshaft withg extra weight on the bearing to make a better balance. |

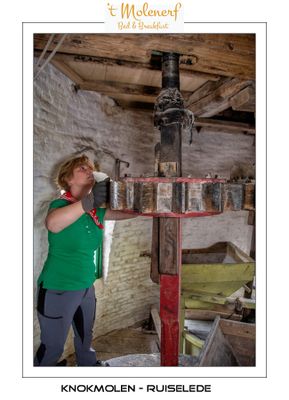

The miller checking the teeth |

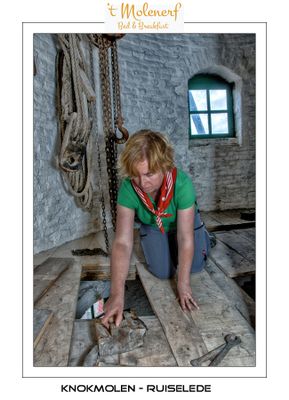

Crawling trough the brakewheel 1 |

Crawling trough the brakewheel 2 |

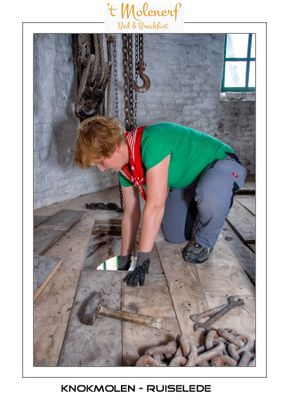

Greasing the front bearing with pork fat |

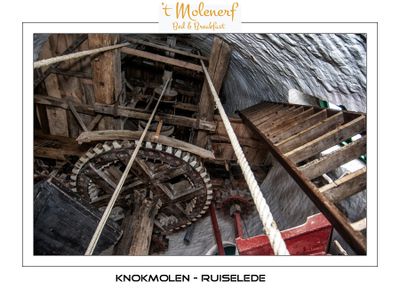

Checking the brakesystem and lowering the rope to operate it. |

Unlocking the brakewheel |

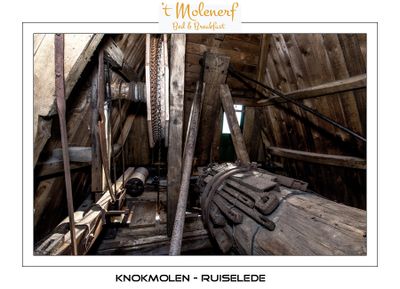

View from the brakewheel towards the back. |

Windshaft with extra weight and left the brakebeam made of metal and some extra weights |

View on the windshafts backend with a lot of extra weight for a better balance and to provide the juming of the end. |

Brakebeam with extra weights added |

Windshaft back bearing |

Windshaft front bearing |

Cap rollers |

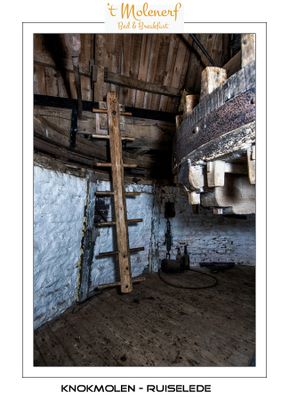

Chicken ladder to go up in the cap |

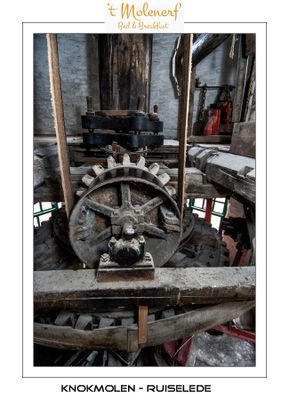

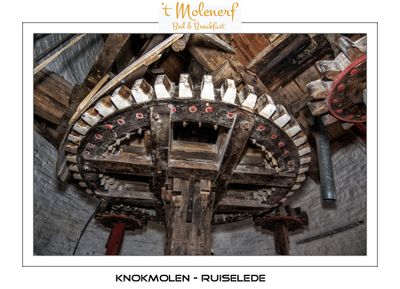

Crownwheel |

Perfect fit and connection |

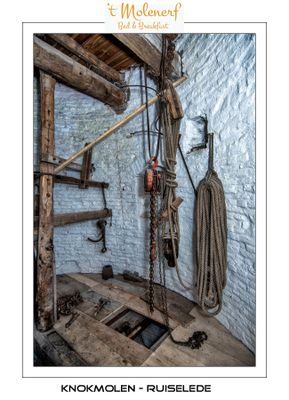

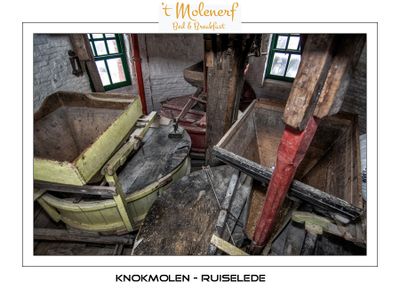

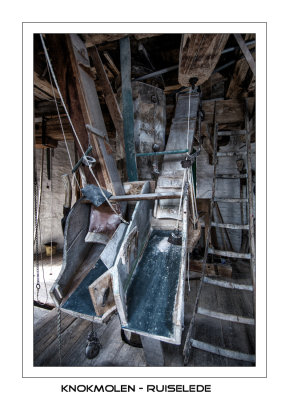

This is the sack hoist floor |

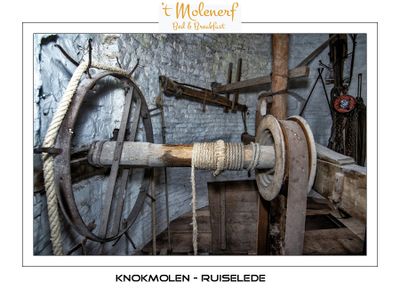

Winch for lifting the millstones when needed. |

Sack hoist system |

The drivegear with belt for the sack hoist system |

Winch with y-wheel |

Drivegear for the sack hoist system |

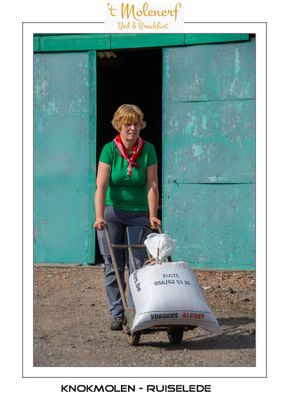

Bringing product from the barn |

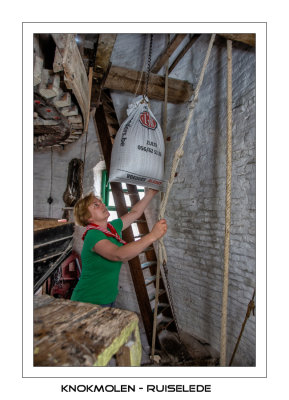

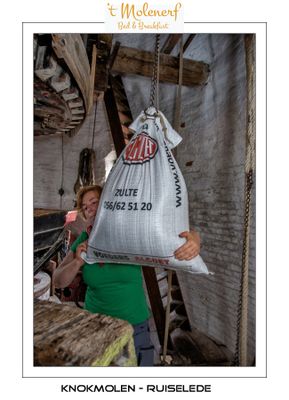

Pulling up the sack with the sack hoist system |

One more floor |

Arriving at the stone floor |

Lowering a bit to put it on the support |

Opening the sack |

Emptying the sack in the hopper |

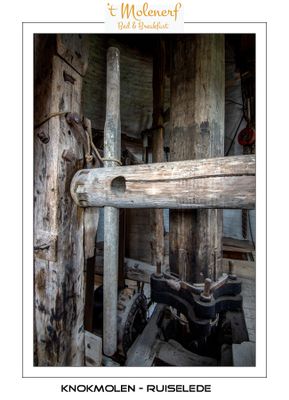

Blocking the shaft with a wooden block |

Fixing the shaft with a wooden block through the floor above |

The miller engages the gear. |

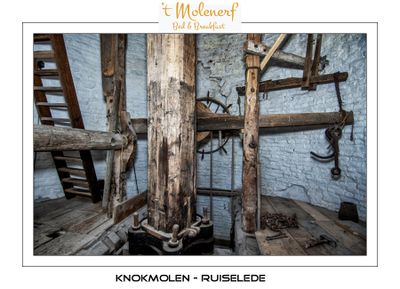

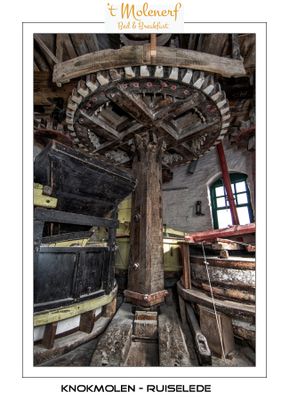

Vertical shaft with spurwheel, cogged pinions and the millstones with wooden casing |

View on the hopper and Iron spindle that drives the runner stone. |

View on the large spurwheel |

The stonefloor with 3 pair of millstones |

Hopper with feed shoe |

Partially opened wood casing from a pair of millstones. |

Connection is OK |

Large spurwheel with smaller cogged pinion gear |

On top of the spurwheel |

The beautiful spurwheel |

Upright shaft with large spurwheel |

A breathtaking view upwards |

The spoutfloor |

The spotfloor 2 |

Double flourchute |

Miller workpost |

At the workpost |

Overseeing the flourchute |

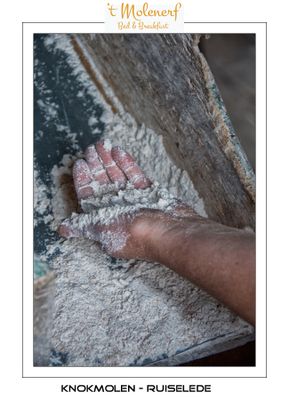

Quality check |

Sack is almost full |

New sack in place |

|

The miller busy with adjusting the process of grinding. |

The controls |

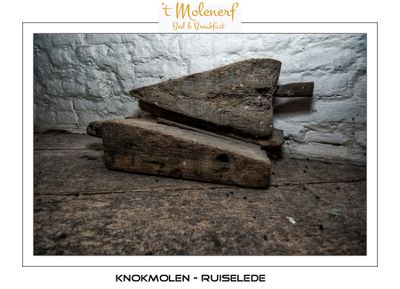

Blocks to put between the millstones if they have to be lifted |

The centrifugal governor |

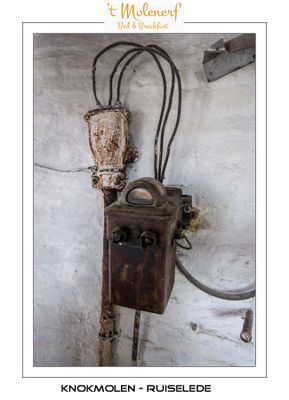

Electricity old style |

A weight of old nuts |

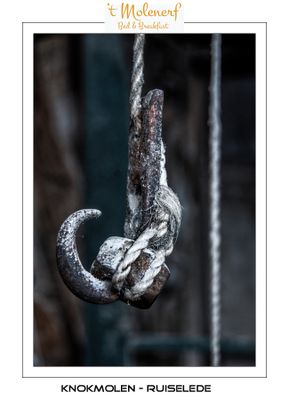

The hook to hold the sack open |

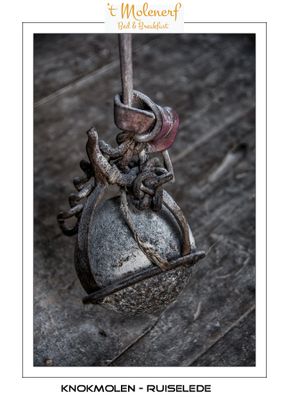

heavy weight for the controls |

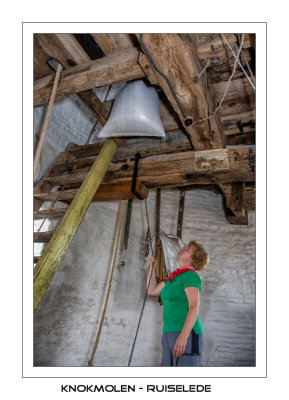

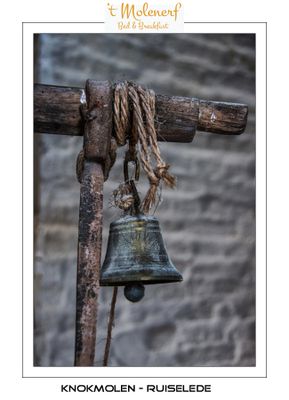

The bell |

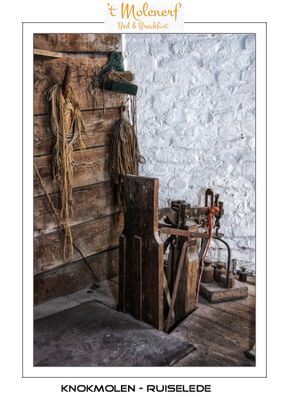

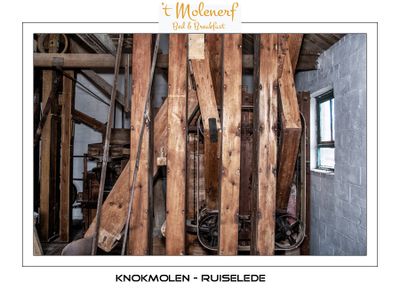

The use of recuperated beams from an old mill |

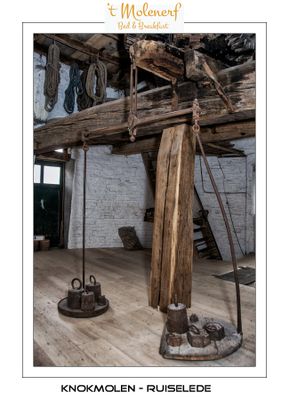

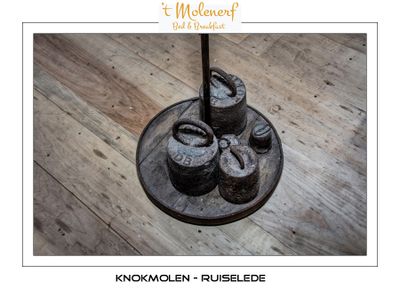

Scale |

Jute sacks |

A huge scale |

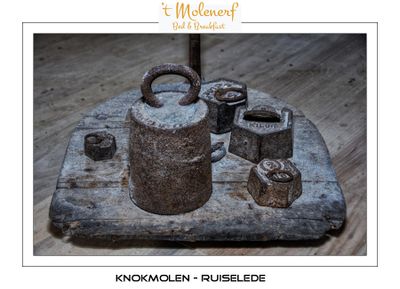

Weights |

Weights |

Flywheel from the engine |

Blackstone Diesel engine 37 HP |

Sifting the flour |

All kinds of machines for processing the grain and flour. |

Elevator system |

Left the belt pulley coming from the dieselengine |

Teaching the next generation |

Pulling the brake to stop the mill |

|

|

|

|

|

|

|

|

|

|

|

|