This is a rotary brush made just for brake rotors |

The brush is made by Brush Research and costs about $35 |

First I loosend the bolts on the back of the caliper |

A lift really helps changing the rear brake pads. Here I have the caliper bolts off and the caliper free |

Here is a look at the two caliper bolts and the pin and pads removed |

Then I removed the rear bolts so I could seperate the back half of the caliper |

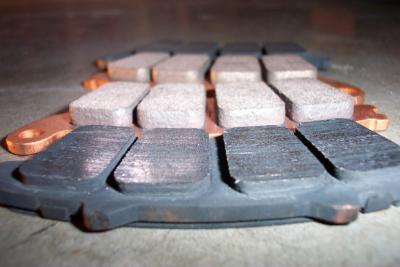

New OEM pads, from DirectLine |

My old pads still had some life left, but I decided not to wait any longer. I had about 2mm left on them. The new pads have 6mm |

Here you can see the thickness of the old and new pads. |

Notice the glaze on the rotor. This is what I want to remove with the brush |

Closer picture of glazed rotor |

The brush is used at a low rpm with light pressure, on both sides of the rotor. I did it with the rotor still installed |

Notice the non-directional pattern afterwards. This is enough to knock off the glaze affect |

I cleaned the rotor with denatured alcohol afterwards. Brake cleaner would also work well. |

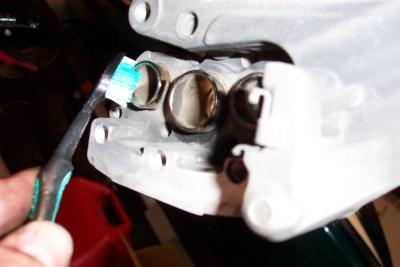

Next, I cleaned the grit off the pistons with a toothbrush and alcohol so I wouldn't push grit into the bore |

Now I can push the pistons back in without contaiminating the seals and cylinders |

A screwdriver handle and firm pressure will push the pistons back into their bores |

You may have to hold the other two while you force the third in, but you should be able to get them all pushed back like this |

You need to remove the backing plate off the old pads and install it on the new ones |

This is the anti-squel backing plate |

It simply pushes onto the new pads |

Here is how the new pad will fit into the back half of the caliper when it is installed |

I also like to remove the slider and lube the slides with some grease |

The bracket fits onto this slide so the caliper can float on the rotor and center itself. It needs to be lubed and free to move |

There is a second slide on the bracket itself |

Push the bracket back into place |

Be sure to remove any excess grease. You don't want it getting on the rotors or pads |

Next, I reinstall the back half of the caliper |

Tighten the rear bolts back up (see manual for torque specs) |

Notice the O ring on the end of the pin. I put a very tiny dab of silicone grease on it |

Here is a look at the pin reinstalled with the new pads hanging down. |

Next, I pushed the outboard pad into place |

You have to push the pad down and into the clip on the right |

Now the other pad is located into the caliper |

It takes some effort, but you MUST get both pads into the retainer clips as shown. |

Here is the view from below after the pads are full seated |

Reinstall the caliper on the rotor, and torque the bolts to spec |

Tightening the pin |

Replace rubber plug, before you ride, pump the rear brake pedal to seat the pads on the caliper. Then break the pads in gently |

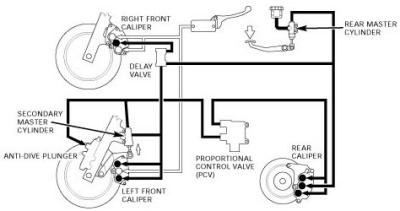

Linked Brake Diagram |

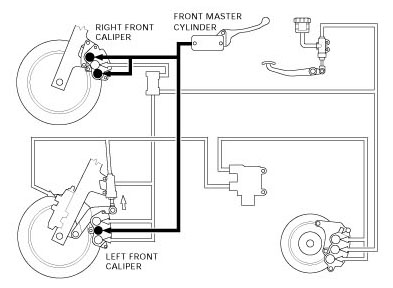

Linked Brake Diagram 2 |

RearBrakePads 001a.JPG |

RearBrakePads 002a.JPG |