Here is the valve body remove from the fork leg, with fork oil all drained out |

Here is a glimpse inside the valve |

Here I am removing the top bleeder mount so I can then remove the upper piston |

Top bleeder assy comes off with a 19mm socket |

Here is a look at the actuator. This is in the off position |

By pushing up on the left brake caliper, you should see the actuator come out as shown here if it is working properly |

The manual advises you to lubricate this actuator. I used silicone grease |

Here is the actuator removed from the upper section of the valve body |

Carfully inspect the O rings. Some have been found to be cut |

Here is a look inside the upper section of the valve body |

This is looking in from the bottom of the lower section with the piston removed |

I lubricated the O rings with silicone grease before re-installation |

Once the valve is back together, if you fill the top with brake fluid before you re-install the bleeder, it will bleed easier |

Home made third hand for helping bleed rear brake system |

Here I am seperating the halves of the valve to look at the lower section |

This is the top of the lower section of the valve |

You have to remove the snap ring to remove the lower piston |

Here is the lower piston removed. There is a spring underneath it. |

Here is a look at the lower piston. Brake bleeder for the top section shown in background. |

Valve fully retracted, protudes 6mm |

Valve fully extended protrudes 9 mm |

When released, valve only retracts 1mm due to tight O rings |

Measuring the resting point of lower valve |

Lower valve resting point is about 9mm |

Add 2 mm for the lip on the edge of the valve body |

Front wheel bearings. Note they are two bearings stuck together by a plastic ring |

The number printed on the bearing is 6004LU |

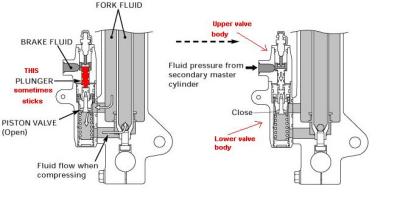

anti-dive valve diagram |

.035 inch shim for anti dive |

Shim is installed under bleeder valve assy |

Shim in place |

Normally there is a 1mm gap between the halves when the upper valve is retracted |

Upper valve normal resting point shows about 6mm protruding |

With shim in place, upper valve now only protrudes 5mm |

With shim in place, no gap occurs and upper and lower valves are just barely contacting |

BlownSeal 006.JPG |