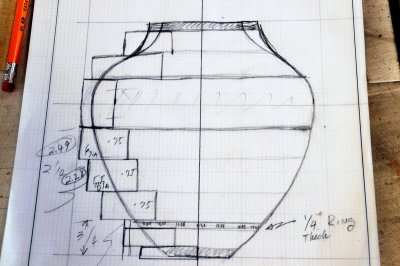

This is a drawing of the bowl I want to make |

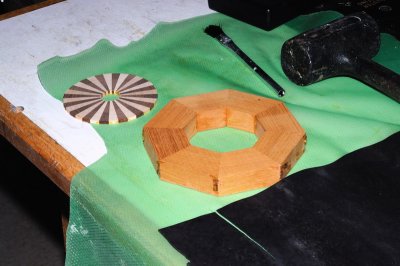

Start by cutting and making ths segment rings |

The base of the bowl is solid walnut |

I use a glue gun to put tabs on the ring to center it |

Put on some glue on both parts |

Put in ring press |

I want a mini feature ring at the bottom between the base and the next ring |

Glue up and put in press |

Add a layer of black veneer |

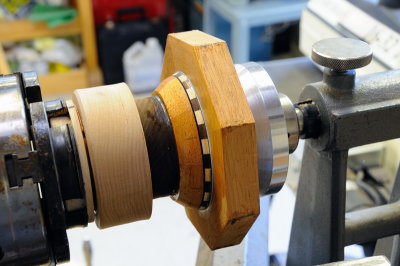

True up on the lathe before adding nex ring |

Use the Oneway ring to center next ring |

Put back on lathe to flatten surface before adding next ring |

Add next ring |

Do a rough turning of outside shape for base |

Add a piece of black veneer before feature ring |

Glue on the feature ring |

Turn the outside to approximate shape |

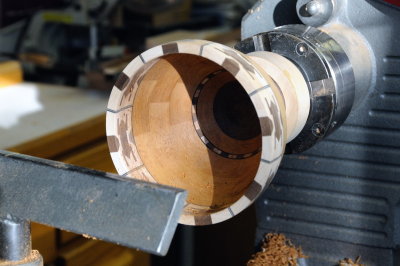

Turn the inside to about 1/4 inch wall thickness |

Now build up the top half rings |

Mate up with the bottom half. I use an adaptor which allows me to attach my chuck to the Oneway live center |

Add a black veneer layer to top half. |

Again join up, and turn the top half to the desired profile |

Now turn the inside of the top section |

This is what the bowl will look like--parts not parted off yet |

Glue the top half to the bottom half |

Part off the top and clean out the opening to the bowl--use the cone on the live center for support |

Part off the bowl---OOPS I got a little carried away with the inside hollowing. No problem! |

Mount the bowl so that I can work on the bottom |

Turn a recess on the foot of the bowl |

Make a plug to fit on the bottom |

Here is the new bottom of the bowl--I used a maple so that I could sign the foot. Looks like I planned it that way. |

Completed bowl |