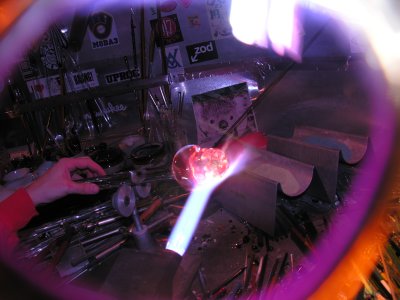

After marvering to a conical shape, Devin applies millies to the cone. |

Applying more millies. |

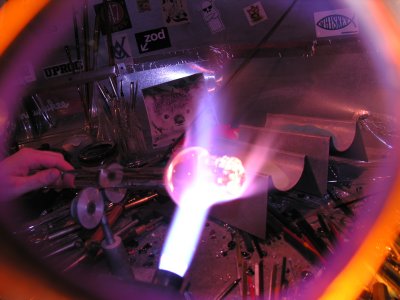

Melting those millies in. |

After a layer of gold fume was applied, Devin adds dark dots over top of that fume. |

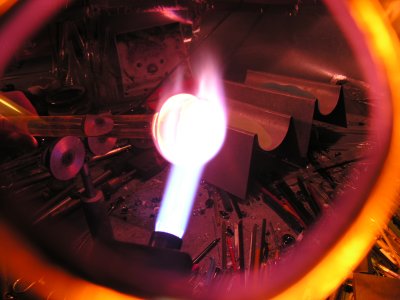

Getting everything nicely melted in. |

Layers of small grain color frit are added to the cone to provide a colored background. |

Pulling the end of the vortex/cone to a nice termination. |

Adding 'junk glass' to the cone in order to round it out. |

More junk glass being added. |

Gathering the large rod to form the lens of the vortex. |

Still gathering..... |

My camera flash fired for this shot... |

You can start to see what the vortex will look like, glowing as it is. |

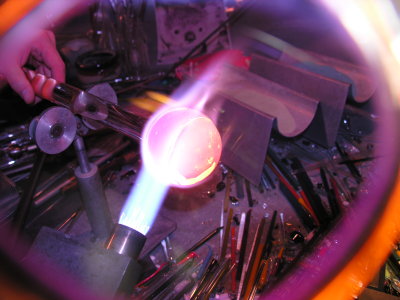

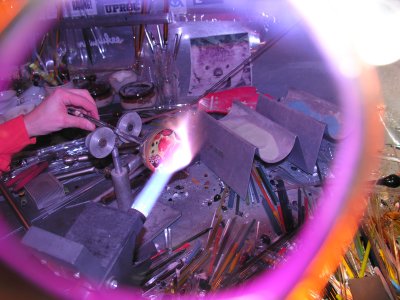

Through the didymium, heating up the mass of junk glass for rounding. |

Still heating.... |

Gravity and heat cause the marble to start to take shape. |

Rounding in the mold. |

Gotta love didymium fire! |

|

Gotta love ANY kind of fire, especially along with glass, woohoo! |

The marble is mostly rounded now. |

Adding several layers of colored frit to the backside. |

Pulling caramel stringer to use to decorate the backside. |

Applying the stringer design. |

|

Melting the design in. |

Here's the hot glowing design through the didymium. |

Final rounding for the backside. |

Melting off the main rod - leaving the right amount of glass for the lens is crucial, and something learned w/ experience. |

Melting and rounding out the lens. |

Almost complete, final rounding in process....my camera battery died! |

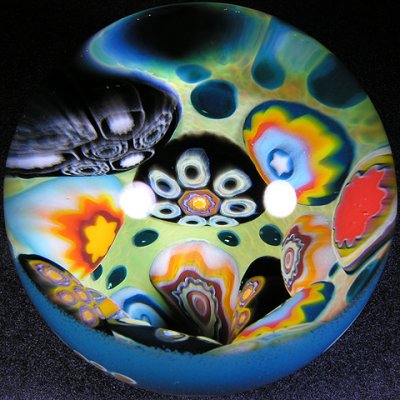

The finished product! |

Look at the twisting of the termination down there, sweet. |

Awesome bright millies! |

You can see the dark dots he placed between the millies. |

See the face? :-) |

Squiggles and wiggles! |