Sheerguard time. Better done before painting. My bad. |

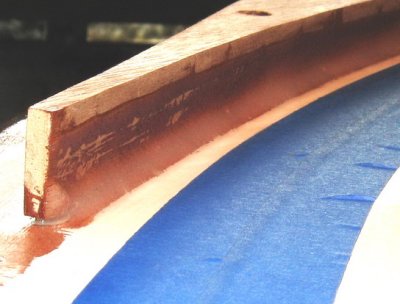

Blue tape marks hidden screw; 2 x 4 holds piece for bending and fitting. |

Another prop during dry fit; Starboard, stern piece. |

Final dry fit, same piece. |

Clamp on wall holds end of aft port sheer guard for correct angle, first screw in. |

Squeezeout, center piece, port side; making fillets a bear, adjacent to paint. |

On to the toe rails; first, nose pieces are dry fitted. Mahogany will be finished bright. |

Quarter inch chisel used to scrape away a landing for fillet. |

Surface scraped of paint and sanded. |

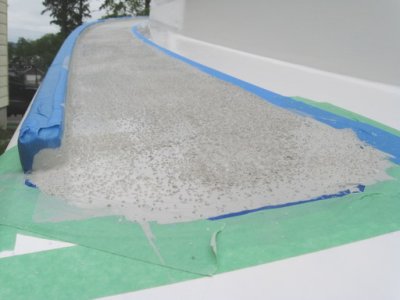

Glueup stage. Masked to keep epoxy over run off the paint. |

Detail of fillet; eventually this will be sanded to the paint under the epoxy for a smooth transition to existing paint. |

Masking removed. Rails will go outside this piece and about 10 feet down each sheer. |

Dry fit of aft portion port rail: lamination phase. |

Glueup of lamination. Tons o' clamps! |

Dry fit of laminated piece prior to gluedown. |

Port rail after gluedown. Screws hold rail in place |

Aft end of glued down rail. |

Joint to forward pieces, prior to cleanup. |

After fitting and glueup to forward pieces, in combined lamination and glueup operation. |

Final gluedown of forward port rail. |

Without the clamps. |

Reglued, patched joint, after lamination glueup; patch will be removed in sanding. |

Pull saw and a dremel cutoff wheel prepare the bow for joining the two rails. |

After a little chisel work, it's ready for a test fit of the starboard piece. I'm ready for that! |

Starboard rail all glued in place. On to sanding and shaping. |

Sanded and ready for resin. |

Couple coats of Silvertip resin on, waiting for it to firm up enough to sand. |

Closeup of bow light and bow chock. Sheer guard will get white paint; toe rail, bright. |

Toerail masked for finishing. |

First coat of clear satin LPU on the toerail. Matte finish area inside will have nonskid on it. |

Plastic lids used as spacers to set the inner mask line for the nonskid on foredeck. |

Masked line. |

Second coat of LPU, prior to adding nonskid. |

Polycarbonate grit applied, port side, with masking. |

Detail of polycarbonate grit; particles are about half a millimeter across and very angular. |

Overall view of completed nonskid; grit was lightly sanded before last coat of LPU to take off some of the bite. |

Hull masking: blue is last color cut in to finish sheer guard and toerail. |

Masking removed after last coat. No more painting! |