A 9 5/8" casing pup joint from a pipeyard for a pier |

Brent cutting the casing |

AD & Brent grinding and grinding.... |

Brent welding |

Above ground pier ready for painting. Below ground pier in background |

Drilling & tapping the flanges to an M8 bolt pattern |

pier ready to go to the site |

The dome arrives |

unpacking the dome |

site topsoil removed |

Drilling a hole for the pier with a 500mm auger. |

24 Nov 2007, Checking the depth of the hole for the pier |

24 Nov 2007, Ramming the fill in the hole |

24 Nov 2007, Re-checking the hole depth |

24 Nov 2007, Checking the base height - a little more clay needs to be taken out |

24 Nov 2007, Taking more clay off a high spot |

25 Nov 2007, Rod takes a break and checks out solar minimum |

25 Nov 2007, Fast spadework from Sharon |

25 Nov 2007, Base levelling. Sharon, Rod & Brent |

25 Nov 2007, Rod in action |

1 Dec 2007, Two pavers were lowered into the hole to form a firm footing for the pier |

1 Dec 2007, The lower ½ of the pier weighing several hundred kg is lowered into the hole |

1 Dec 2007, The pier boxed vertical with pegs, and with 2 bolt holes pointing North |

1 Dec 2007, Mixing concrete for the pier inner and annulus |

15 Dec, Rod working on the reinforcing mesh |

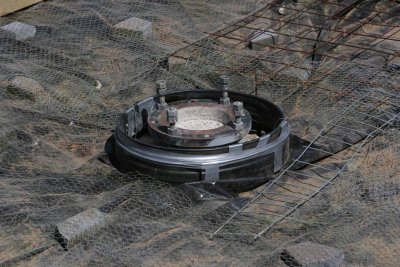

15 Dec, The reinforcing completed |

15 Dec, Boxing around the pier |

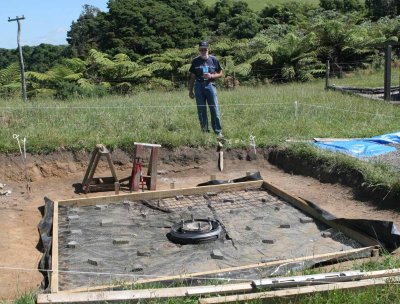

15 Dec, Ready to pour concrete |

20 Dec, Ian with the mixer he borrowed, checking the weather ? |

20 Dec, The concrete mixed and the pad poured |

20 Dec, Ian celebrates |

20 Dec,Final touches |

20 Dec, scrubbing down the screeding timber to re-use for the framing,- well it's $7/m ! |

9 Feb, Cutting the framing |

9 Feb, 2 walls up, 2 to go. The photo isn't sharp, but the light was fading |

10 Feb. Rod measures the cladding ready for cutting. I had to change the contrast on this pic, it was washed out with the rain |

10 Feb. The assembled walls & DPC laid, - all ready for Dynabolting |

11 Feb. 3 of the wall frames have been bolted to the pad. The 4th will be done after the pad has been used to assemble the dome |

12 Feb The assembled dome (less shutters) ready for mounting. Brent lend a hand to bring the assembled dome back in from the pad |

12 Feb. All the wall frames up and ready for cladding |

13 Feb. The offending Dynabolt in the East (last) wall, - in place at last |

13 Feb. The dome now on the assembled ring, with the dome wheels on |

13 Feb. A close up of the dome wheels seen from above. (before the top gaurds are installed) |

The framing with some extra nogs to support the corner flashing. The framing is braced to ensure the diagonals are equal, |

15 Feb. The framing braced to ensure the building is 'square' as the cladding goes on. |

15 Feb. The cladding more than half way complete. Yep, not as hot up there today with the wind blowing |

16 Feb. The cladding is completed, (the corners will be flashed) and the dome support framing is started. |

17 Feb. The support frame for the dome has been started |

19 Feb. Cutting the ply for the door |

20 Feb. Infill nogs to support the dome ring |

22 Feb. Jigsawing out the curve in the roof panels to take the dome ring. Cut panels in the background. |

22 Feb. Routering out a 5 mm channel in the 12mm ply to accept a tongue for the butt joints. Channel detail inset |

28 Feb. Work on the 26-28 Feb has completed the ply roof and dome ring. The ply will be flashed & glassed |

28 Feb, Exterior detail of the tongue in the ply butt joints |

28 Feb. Interior detail of the dome ring. There's a 3mm foam seal between the base of the glass ring and the ply |

29 Feb. Door detail |

29 Feb. With help from Murray & pup Herman, the dome is now on. The dome rotates with just finger pressure. |

3 Mar. Going over the door edges with the plane. |

3 Mar. Chiseling out the door lock mortice |

3 Mar. Marking out and checking out the door for the hinges. |

3 Mar. Checking out for the door hinges |

3 Mar. Attaching the upper shutter motor |

3 Mar. Uppr shutter motor detail |

3 Mar. Screwing the dome rotation toothed bars on |

11 Mar. Obs. interior. Dome rotation control box on LHS with remote switch. |

22 Mar. The obs. with flashings. Looking SE |

22 Mar. The obs from the West showing the door |

22 Mar. The bench for the PC's etc |

22 Mar. Bench detail |

12 Apr 2008, Photo by Melanie Cooper, Carrying the 14" LX200R out to the observatory. (115 lbs) |

12 Apr 2008, Photo by Melanie Cooper, ABout to take the 14" LX200R into the observatory |

12 Apr 2008, Photo by Melanie Cooper, Myself & Murray holding it up to the wedge, & Rodney putting the cap screws in |

12 Apr 2008, Photo by Melanie Cooper, The scope on the pier |

12 Apr 2008. Photo by Rod Austin. Melanie's shooting position |

12 Apr 2008, The 14" LX200R mounted |

12 Apr 2008, The 14" LX200R mounted |

31 May 2008, Mounting the 10w solar panel to keep the shutter battery charged Deb assisting 39 weeks pregnant |